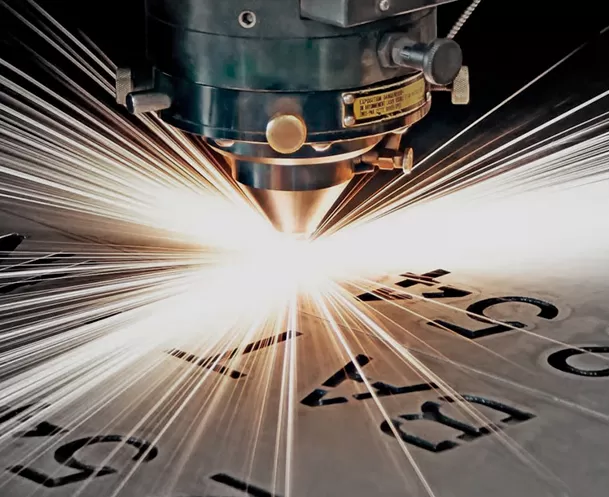

This type of cut consists on the concentration of many beams of light highly focused. When in contact with the plate the metal heats this way melting or turning into steam. As advantages it makes complex geometric cuts. Works with metallic and non-metallic and leaves a few burrs. As handicap this process is suitable for cutting materials with thicknesses between 0.5 mm and 10 mm thick and has a high energy consumption.In addition to steel sheets, it is possible to work with fiberglass reinforced structures.

This type of cutting is done by heating a gas at high temperatures as long as the material conducts electricity. The main advantage, compared to oxyfuel, is the use of a smaller cutting zone and a higher operating speed reducing the risk of deformation. Ideal for thicknesses up to 2 inches however in recent technological updates, you can find models that drill between 75mm and 160mm. It can be used for ferrous and non-ferrous materials even if they have oxidized, painted, sanded or scraped surfaces.

This type of cut is made from a mixture of fuel gas and oxygen. Normally the part is heated to very high temperatures (close to 900°c for steel), then a stream of oxygen is used which forms iron oxides as this reaction is significantly exothermic, the metal is broken in two parts. Used more for ferrous steels such as carbon steel and not used for stainless steel, as it does not work with non-oxidizing metals. In addition to these points discussed it is important to note that for parts over two inches and thicker in addition to materials that do not require much precision in cutting, oxyfuel is a more advantageous option.

This option consists of generating a jet of water at very high pressures, normally mixed with abrasive material (eg Silica). As it is a cold cut, the difference from the other processes is not to overheat the material used. It also consists of a cut that can be made to most materials and with a high level of precision. With this option it is possible to drill steel up to 300 mm and other high hardness materials (eg Titanium). However, it has a high cutting cost only equivalent to laser cutting and a lower cutting speed.

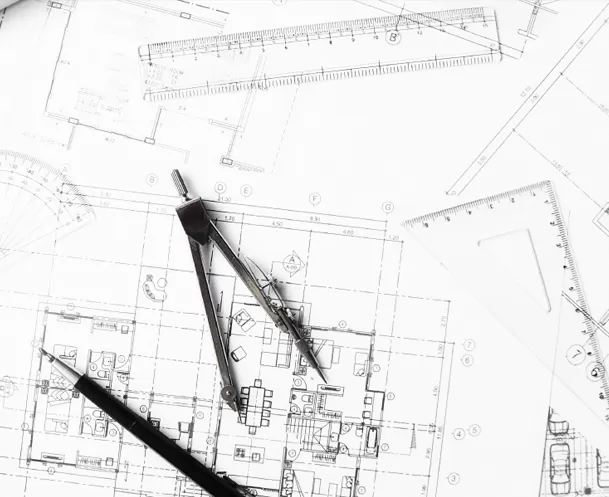

Technical drawing is a graphic representation used in engineering and other areas that presents characteristics such as cuts, views and scales. It is standardized by ABNT (Brazilian Association of Technical Standards).In this case we will be responsible for putting your ideas on paper in a technical and professional way so that your project can be successfully developed.

To facilitate the creation of your project we carry out up to five free technical drawings per company. Send us your idea and we'll help you out!

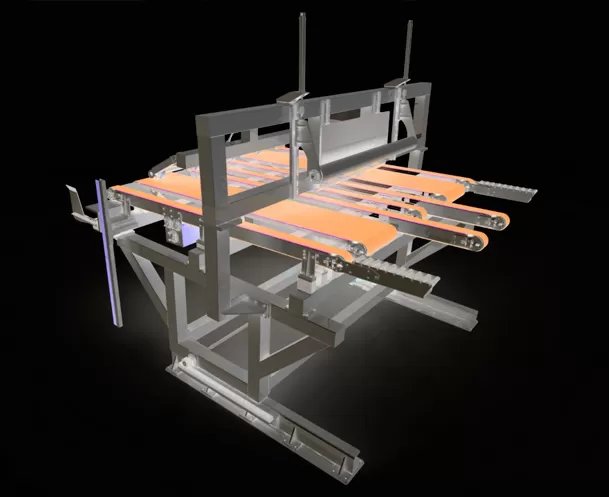

It is a mechanical forming operation that consists of folding and bending steel sheets or metallic tubes. Bending occurs due to the application of a bending moment capable of plastically deforming the material.

By bending bent sheets can be obtained with several predetermined bending angles for example: boxes, profiles, protection, housing for machines and equipment.

Calendering is a mechanical forming process used to bend a certain material such as metal sheets or profiles (Laminated or Drawn).

By Calendering curved plates with predetermined bending radii can be obtained. For example: Cylinders, Cones, Cone trunks, curved segments and ferrules.

We understand all steel forming processes. This allows us to create your prototype easily and quickly.

We are ready to help you from the conception of the idea and project development to the production of it.

Being a shared manufacturing company allows us to serve you in all your particularities.

Laser cutting on pipes is performed by specialized laser cutting machines that use a high-power laser beam to cut pipes in various shapes and sizes. The laser cutting process is controlled by a computer software that reads a design or drawing in digital format and uses the information to guide the laser beam to cut the pipe.

It also has the ability to cut materials with varying thicknesses. It is used in various sectors, including the automotive, aerospace, naval, construction and other areas that require precision pipes.

And discuss how our solutions and tools can contribute to your production?

Appointment to a coffee© Bessemer 2024All rights reserved.

Design by